Modeling Software for Composites and Advanced Materials

AnalySwift is a provider of efficient high-fidelity design software for modeling composite materials and structures, and other advanced materials. AnalySwift allows users to achieve 3D FEA accuracy at the efficiency of simple engineering models. Offering two tools, VABS and SwiftComp, AnalySwift is for users seeking to save simulation time without a loss of accuracy. By enabling drastic reductions in engineering time and facilitating earlier virtual testing, AnalySwift empowers businesses to bring innovative products to market faster. Engineers modeling composites can consider more design options, also resulting in arriving at the best solution quicker to accelerate time to market while reducing costs.

SwiftComp by AnalySwift

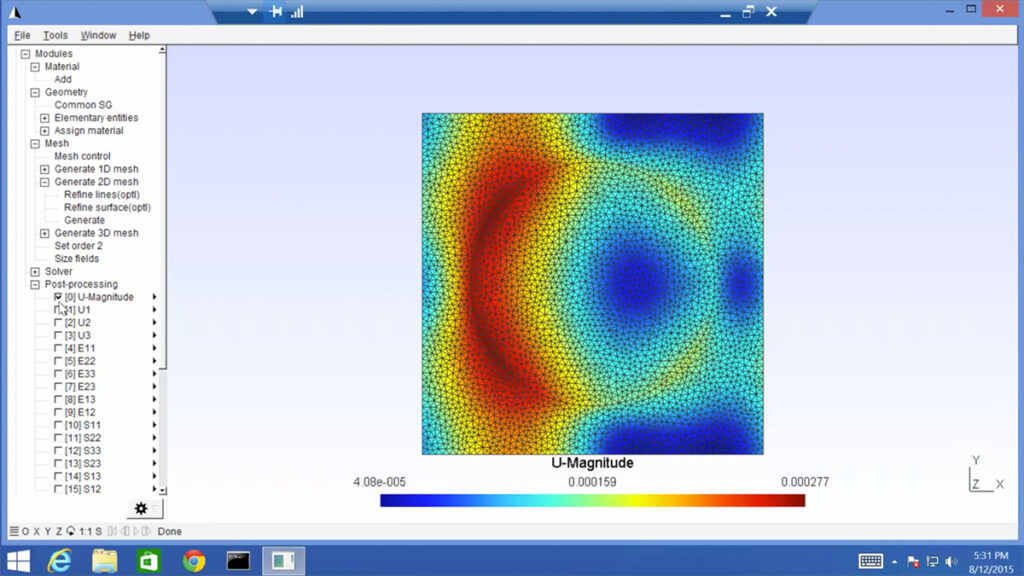

SwiftComp is a groundbreaking software for modeling composite materials with exceptional efficiency and accuracy. It bridges the gap between microscopic material behavior and macroscopic structural performance. Unlike traditional methods, it allows engineers to model composites as easily as metals within existing FEA software. This one-stop solution offers multiscale modeling for various structures (beams, plates, 3D) while capturing intricate details. Use SwiftComp independently or as a plug-in for existing tools (it directly interfaces with ANSYS Workbench & Classical), making it highly versatile for diverse applications. SwiftComp surpasses typical RVE analysis by delivering 3D properties and local fields more efficiently using lower dimensional domains and fewer calculations. It revolutionizes composite simulations by seamlessly connecting microstructural details with overall structural behavior.

Key Features

- Unified Multiscale Modeling: Analyzes composites at various scales (beams, plates, 3D structures) while capturing intricate details. Infuse 3D FEA fidelity into earlier design stages at the efficiency of simple engineering models.

- Exceptional Efficiency: Delivers accurate results significantly faster than traditional methods. Reduced engineering time for even the most complex composites.

- Simplified Workflow: Enables engineers to model composites just like metals within existing FEA software. Facilitate the use of your composite simulation tools by unifying micromechanics and structural mechanics into a single technology.

- Versatility: It can be used independently or as a plug-in for various structural analysis tools, such as Ansys (Workbench & Classical). Power your conventional FEA packages with high-fidelity multiscale, multiphysics composites modeling.

- Broad Applicability: Simulates a wide range of composites beyond traditional materials. Harness the full potential of composites in your design by capturing both anisotropy and heterogeneity.

Benefits

- Harness the full potential of composites in your design by capturing both anisotropy and heterogeneity as needed and a ordable.

- Use structure genome to reduce engineering time orders of magnitude.

- Infuse 1st principle 3D FEA fidelity into earlier design stages at the efficiency of simple engineering models, while minimizing information loss.

- Simplify acquiring, training, and use of your composite simulation tools by unifying micromechanics and structural mechanics into a single technology.

- Get the most out of your conventional FEA packages as SwiftComp empowers them with high-fidelity multiscale modeling for composites.

- Reuse your tools for design and analysis of metals by providing a right approach to model composites as a homogeneous continuum capturing all the microscopic details.

Applications

MULTISCALE MODELING OF COMPOSITES

- 3D composite structures: binary composites, fiber

reinforced composites, particle reinforced composites,

textile composites, short fiber composites, porous

materials, foams, and other heterogeneous materials - Composite plates/shells: laminates, stiffened panels,

corrugated structures, perforated structures, sandwich

structures, unitized structures, and more - Composite beams: helicopter rotor blades, wind

turbine blades, high-aspect wings, golf clubs, fishing

rod, and other slender composites structures

VIRTUAL TESTING OF COMPOSITES

- Mechanical properties: elastic constants,

static strength - Conductivities, dielectric, magnetic,

and diffusive properties - Coefficients of thermal expansion

and specific heat - Electromagnetic properties

VABS by AnalySwift

VABS is a general-purpose, cross-sectional analysis tool specifically designed for the cost-effective modeling and simulation of complex composite materials such as composite rotor blades, tubes, and other slender composite structures. It allows engineers to analyze these composite structures with unmatched detail and efficiency. The latest version of VABS blade modeling software offers additional capabilities, including calculating the strength and safety of cross sections under given loads. Besides helicopter and wind turbine rotor blades, VABS has more recently proved to be popular for growing applications in air mobility (AAM, UAM, eVTOL, etc.). Originally developed to address the challenge of quickly and accurately modeling complex helicopter rotor blades, the VABS software rapidly found applications helping engineers in a wide variety of industries. Also used today for wind turbines, urban air mobility, landing gear, industrial tubes, golf clubs, and fishing rods, VABS provides engineers with an even better understanding of the products they are designing or analyzing.

Key Features

- Cross-Sectional Analysis for Slender Structures: VABS focuses on analyzing the cross-section of slender structures, particularly those featuring complex materials like composites.

- Accurate Beam Property Calculations: It delivers highly accurate calculations for a complete set of beam properties, crucial for structural analysis.

- Recovers 3D Stresses and Strains: VABS goes beyond basic properties, allowing recovery of 3D stress and strain data within the composite beam.

- Explicit Ply Details Modeling: VABS explicitly models all the details of individual plies (layers) within the composite material, leading to more precise simulations.

- Matches Accuracy of 3D FEA with Efficiency: VABS achieves the same level of accuracy as complex 3D Finite Element Analysis (FEA) simulations, but with significantly higher efficiency.

- Ideal for Design Optimization: With its efficient and accurate analysis, VABS is well-suited for optimizing the design of composite beams.

- Suitable for Various Composite Structures: VABS can handle a broad range of composite structures, including helicopter and wind turbine rotor blades, propellers, landing gear, and more.

Benefits

- Unprecedented competitiveness as the only available technology to rigorously model real structures such as composite blades.

- It accommodates truly arbitrary geometries, no need of oversimplified approximations of real structures.

- Drastically reduced design cycle and time to market by helping you save significant engineering design and analysis time.

- The best compromise between accuracy and efficiency, an effective alternative for computation-intensive 3D FEA.

- An enabling technology for nonlinear aeroelastic analysis of highly flexible structures.

- Multiphysical capability, as VABS can analyze structures under the coupled effects of thermal, mechanical and electromagnetic fields.

- Various engineering beam models, without ad-hoc assumptions (generalized Euler-Bernoulli model, Timoshenko model to account for transverse shear, and Vlasov model for constrained warping).

- Modeling of initially twisted, curved, or oblique beams.

- Recovery of field variables: recovers 3D stresses, strains, and displacements directly from 1D data for accurate analysis.

- Accounts for trapeze effect. It analyzes beams under high centrifugal loads considering the nonlinear impact on torsional stiffness.

Applications

AREAS

- Wind turbine blades

- Helicopter rotor blades

- eVTOL, UAM, UAV, UAS, AAM, ODM, and ORB blades

- Propellers

- Landing gears

- Gas turbine blades

- High-aspect ratio wings

- Wing section design

- Composite bridges

- Golf clubs

- Fishing rods

- Other slender or general composite/smart structures, as beams, shafts, rods, columns, bars, etc.

MATERIALS

VABS is NOT restricted by materials. The structure can be made of an arbitrary number of general materials including isotropic, orthotropic, or general anisotropic materials like:

- Fiber reinforced composites

- Woven composites

- Braided composites

- Conventional materials

- Foam materials, and others.